We guarantee that all of our engraved brick and tile products will remain free from any engraving defects for the lifetime of the product. If you have an issue with a delivered order, we will resolve it immediately by replacing any defective engraved bricks free of cost- and hassle-free.

To prove how durable our engraved bricks are, we subjected our laser engraved bricks to a simulated 50-year weather resistance test by an independent testing laboratory in St. Louis, MO. The laser engraved bricks were subjected to three extreme weather climates: Freeze-Thaw Cycling (hot and cold extremes), Ultraviolet Rays (exposure to direct sunlight with heat), and Salt Spray (snow, ice, rain). Lab results proved that even under the most extreme weather conditions, the laser engraved bricks stood the test of time, ensuring that you will never need to replace your brick.

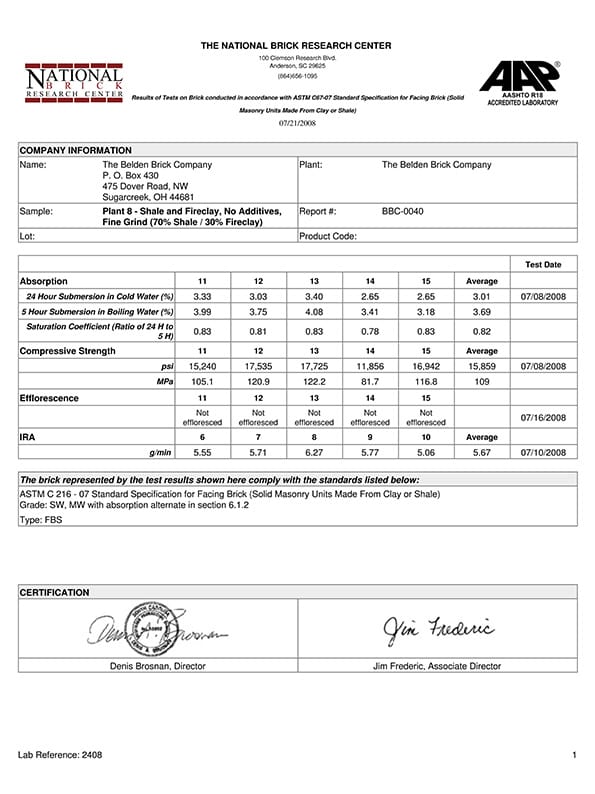

Fundraising Brick warrants, through its Limited Lifetime Warranty, that its patented brick laser engraving processes will be of good quality and workmanship and will not fade, chip, oxidize, peel or separate from the brick, paver or tile for the life of the surface of the engraved brick, paver or tile. Fundraising Brick requires that the brick, paver or tile manufacturer meet all American Standards of Testing Materials (ASTM) standards for quality, durability and longevity. There are some brick manufactures that are excluded from our laser engraved warranty.

This warranty is limited to the repair or replacement of any laser engraving processes onto brick, pavers or tile meeting ASTM standards. There are some brick manufactures that are excluded from our laser engraved warranty. Any laser engraving process that prove(s) defective will be repaired or replaced by Fundraising Brick provided that such defect is due to faulty material or workmanship on the part of Fundraising Brick and not the result of tampering, vandalism, misuse, abuse, improper installation or maintenance misapplication, natural disaster or acts of God, excluding normal environmental conditions such as rain, sleet, snow and freeze/thaw conditions.

Contact us today to learn how we can help get your fundraiser off the ground!

Brick Durability Standards

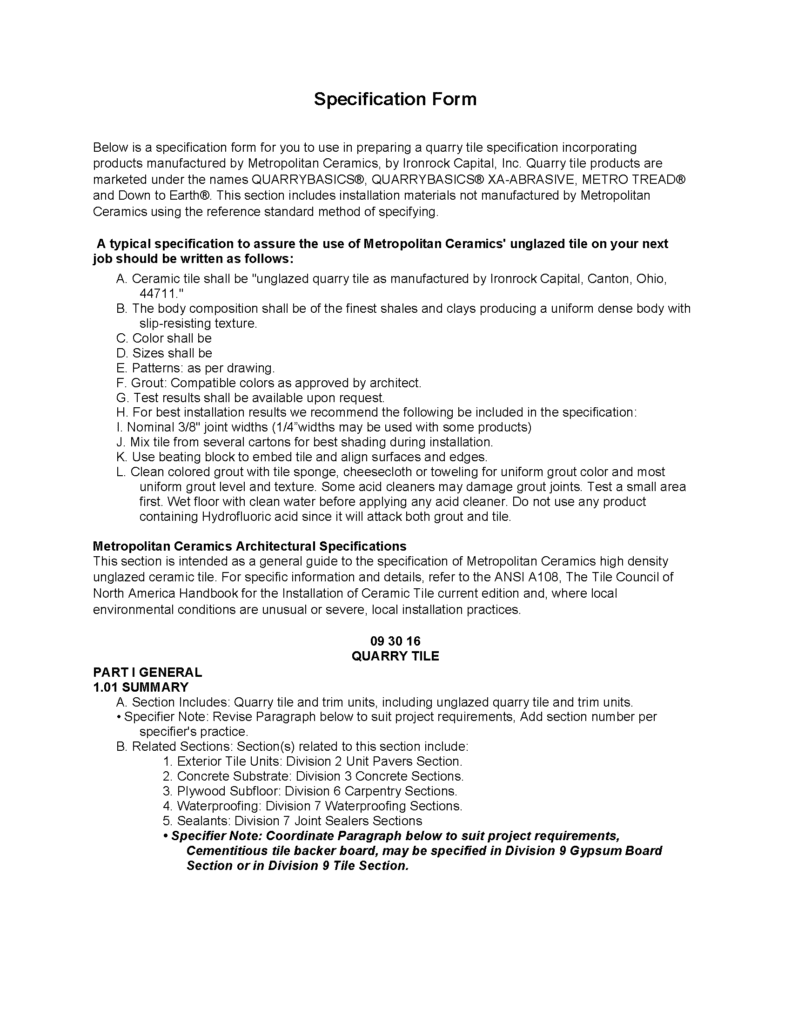

Please see the PDF links below for additional details on Brick Durability Standards and Tile Specifications:

Laser Engraved Brick Durability Standards

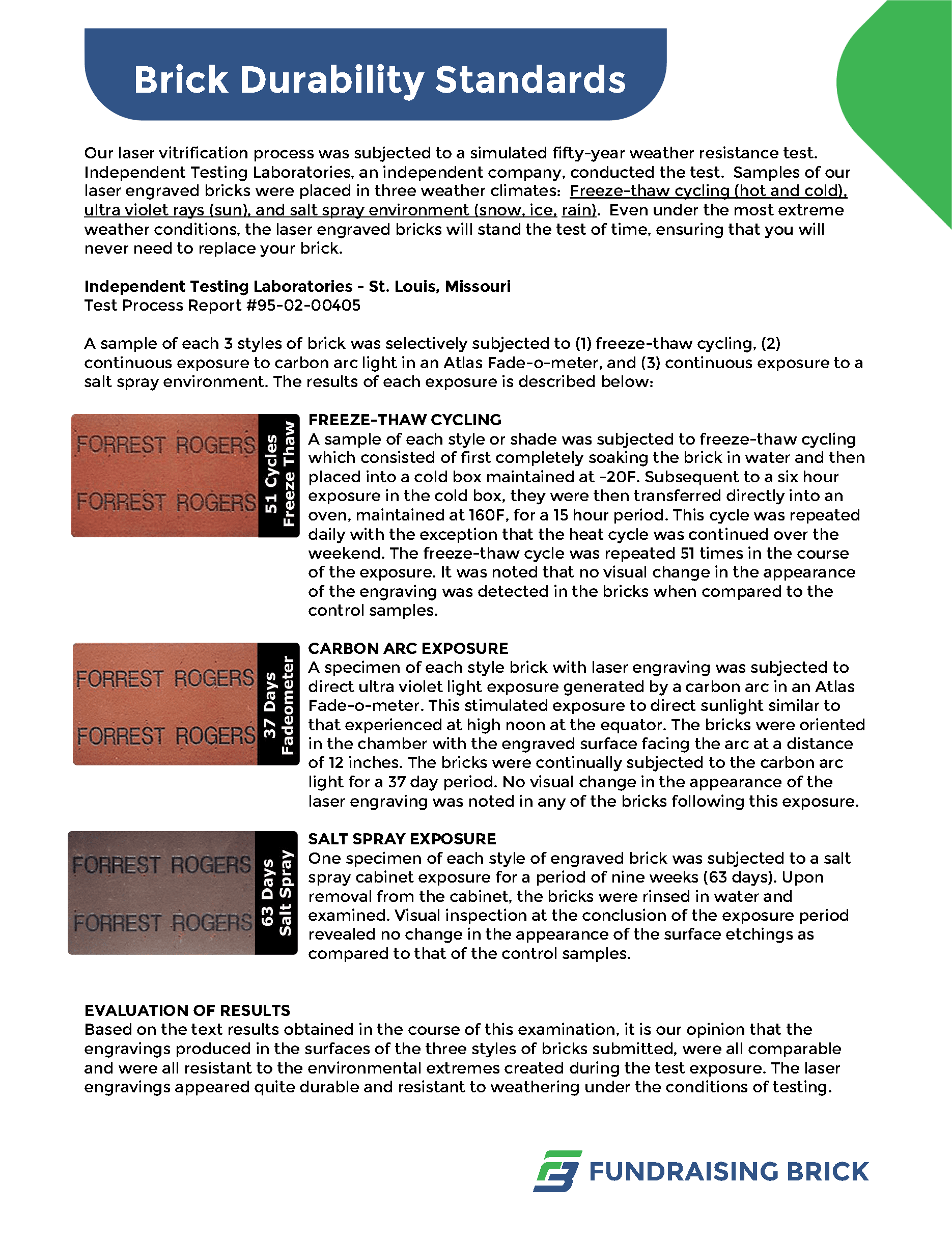

Our laser vitrification process was subjected to a simulated fifty-year weather resistance test. Independent Testing Laboratories, an independent company, conducted the test. Samples of our laser engraved bricks were placed in three weather climates: Freeze-thaw cycling (hot and cold), ultra violet rays (sun), and salt spray environment (snow, ice, rain). Even under the most extreme weather conditions, the laser engraved bricks will stand the test of time, ensuring that you will never need to replace your brick..

Independent Testing Laboratories – St. Louis, Missouri

Test Process Report #95-02-00405

A sample of each 3 styles of brick was selectively subjected to (1) freeze-thaw cycling, (2) continuous exposure to carbon arc light in an Atlas Fade-o-meter, and (3) continuous exposure to a salt spray environment. The results of each exposure is described below:

FREEZE-THAW CYCLING

A sample of each style or shade was subjected to freeze-thaw cycling which consisted of first completely soaking the brick in water and then placed into a cold box maintained at -20F. Subsequent to a six hour exposure in the cold box, they were then transferred directly into an oven, maintained at 160F, for a 15 hour period. This cycle was repeated daily with the exception that the heat cycle was continued over the weekend. The freeze-thaw cycle was repeated 51 times in the course of the exposure. It was noted that no visual change in the appearance of the engraving was detected in the bricks when compared to the control samples.

CARBON ARC EXPOSURE

A specimen of each style brick with laser engraving was subjected to direct ultra violet light exposure generated by a carbon arc in an Atlas Fade-o-meter. This stimulated exposure to direct sunlight similar to that experienced at high noon at the equator. The bricks were oriented in the chamber with the engraved surface facing the arc at a distance of 12 inches. The bricks were continually subjected to the carbon arc light for a 37 day period. No visual change in the appearance of the laser engraving was noted in any of the bricks following this exposure.

SALT SPRAY EXPOSURE

One specimen of each style of engraved brick was subjected to a salt spray cabinet exposure for a period of nine weeks (63 days). Upon removal from the cabinet, the bricks were rinsed in water and examined. Visual inspection at the conclusion of the exposure period revealed no change in the appearance of the surface etchings as compared to that of the control samples.

EVALUATION OF RESULTS

Based on the text results obtained in the course of this examination, it is our opinion that the engravings produced in the surfaces of the three styles of bricks submitted, were all comparable and were all resistant to the environmental extremes created during the test exposure. The laser engravings appeared quite durable and resistant to weathering under the conditions of testing.